-

- Industry

- Material

- Capability

- Products

- Blog

- Sitemap

- Newsletter

- Whatsapp 8615951276160

- Industry

- Material

- Capability

- Products

- Blog

- Sitemap

Unlocking the Potential of Reliable Aluminum Bending with SourcifyChina Factory: Streamline your production process with high-quality aluminum bending services straight from the source.

“SourcifyChina aluminum bending offers precise and custom metal bending solutions for various industries. This service ensures high-quality products with accurate measurements and angles.”

“By outsourcing aluminum bending to SourcifyChina, businesses can save time and resources. This allows them to focus on core activities and increase overall productivity.”

“SourcifyChina’s expertise in aluminum bending guarantees durable and reliable components. Their team utilizes advanced technology and techniques to deliver top-notch results.”

“Partnering with SourcifyChina for aluminum bending can improve efficiency and reduce production costs. This leads to a competitive edge in the market and higher profitability for businesses.”

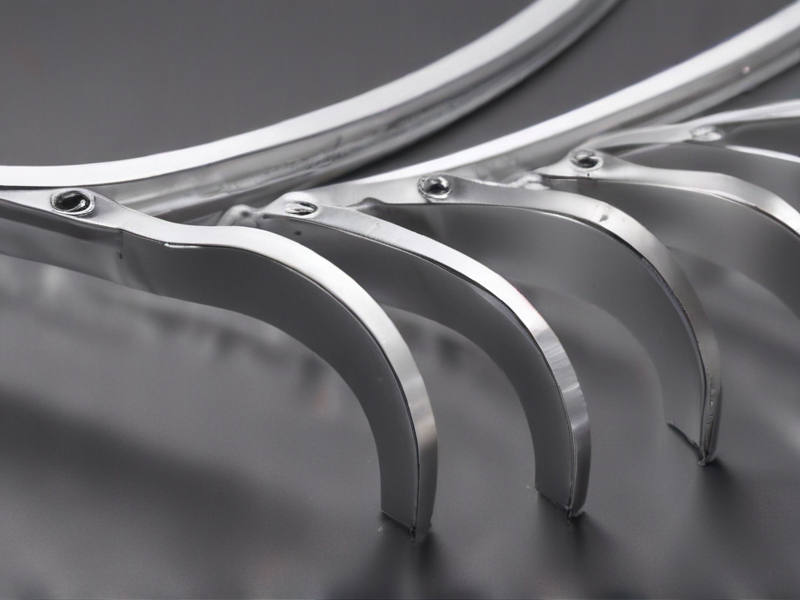

SourcifyChina offers aluminum bending services with precision accuracy and quick turnaround times. Our skilled technicians can bend aluminum sheets up to 12 feet in length, using state-of-the-art equipment for consistent results.

Our aluminum bending process ensures smooth, uniform bends without any distortions or warping. We guarantee a precise bend angle with tight tolerances, allowing for seamless integration into your project.

SourcifyChina utilizes a variety of bending techniques such as air bending, bottoming, and coining to achieve the desired shape. Our team of experts can work with various aluminum alloys to meet your specific requirements.

We take pride in our ability to bend aluminum with high efficiency and accuracy, saving our customers time and money. Our streamlined process minimizes waste and maximizes productivity, ensuring a cost-effective solution for your bending needs.

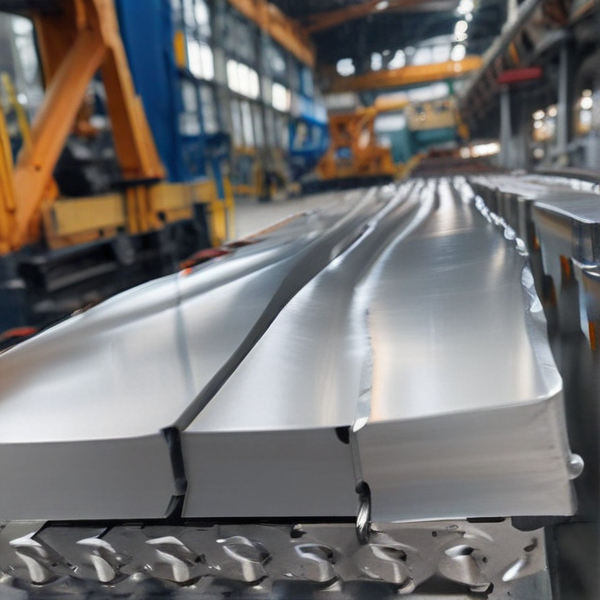

Sourcify’s China Factory offers aluminum bending services for various types of projects. They can bend aluminum sheets, pipes, and profiles to create customized products for industries such as automotive, aerospace, and construction.

Aluminum bending can be done through processes such as roll bending, press bending, and rotary draw bending. These methods allow for precise bending angles and shapes to meet specific design requirements.

Applications for aluminum bending include manufacturing of car parts, structural components, and architectural elements. The flexibility of aluminum allows for lightweight, durable, and corrosion-resistant products to be produced.

Whether it’s for prototyping, mass production, or custom projects, Sourcify’s China Factory has the capabilities to meet the aluminum bending needs of various industries. Their experienced team and state-of-the-art equipment ensure high-quality results that exceed customer expectations.

SourcifyChina Factory is a top choice for buyers purchasing aluminum bending from China due to their expertise in manufacturing high-quality products. With years of experience in the industry, they have gained a reputation for their superior craftsmanship and attention to detail.

Furthermore, SourcifyChina offers competitive pricing on their aluminum bending products, making them an affordable option for buyers looking to save on costs. They work closely with clients to ensure their needs are met and deliver products that meet or exceed expectations.

In addition, SourcifyChina Factory has a streamlined production process that allows for quick turnaround times and efficient delivery of orders. This ensures that buyers receive their aluminum bending products in a timely manner, without any delays or setbacks.

Streamlining Production: Maximizing Efficiency with Sourcify’s China Factory Aluminum Bending

In today’s competitive manufacturing landscape, efficiency is key. With Sourcify’s China Factory Aluminum Bending services, businesses can streamline their production processes and maximize their output. By leveraging advanced bending technology and expertise, companies can reduce lead times, eliminate bottlenecks, and ultimately improve their bottom line.

From small-scale prototypes to large-scale production runs, Sourcify’s aluminum bending capabilities can meet a wide range of manufacturing needs. Whether it’s creating complex shapes or precision parts, Sourcify’s experienced team can deliver high-quality results with quick turnaround times. By outsourcing aluminum bending to Sourcify’s China factory, businesses can focus on other aspects of their operations and trust that their bending needs are in capable hands.

SourcifyChina Factory aluminum bending is a valuable tool in the automotive industry for the creation of various components that require precision bending of aluminum. Aluminum is commonly used in the automotive industry for its lightweight properties, durability, and corrosion resistance. With SourcifyChina Factory’s expertise in aluminum bending, manufacturers can produce a wide range of components such as frames, brackets, and panels that are essential for the construction of vehicles. The process of bending aluminum allows for intricate designs to be formed with accuracy and consistency, ensuring that the final product meets the high standards required in the automotive industry.

SourcifyChina Factory offers a specialized aluminum bending service that is highly sought after in the equipment manufacturing industry. Aluminum is a versatile material that is lightweight yet durable, making it ideal for a wide range of applications. By utilizing SourcifyChina Factory’s aluminum bending capabilities, equipment manufacturers can create custom parts and components that meet their specific design requirements. Whether it is bending aluminum tubes, sheets, or profiles, SourcifyChina Factory has the expertise and equipment to handle complex bending tasks with precision and efficiency.

The Sourcify China Factory aluminum bending process is widely utilized in various industries for its efficiency and precision in producing high-quality aluminum components. In the automotive industry, aluminum bending is utilized in the manufacturing of vehicle frames, chassis, and body panels. The lightweight and corrosion-resistant properties of aluminum make it an ideal material for enhancing fuel efficiency and overall performance of automobiles. Additionally, the ability to bend aluminum into complex shapes and angles ensures that the components fit seamlessly within the vehicle design.

SourcifyChina Factory ensures high-quality aluminum bending through strict quality control measures. They have a team of experienced inspectors who closely monitor the production process to ensure that all products meet the required standards. By implementing rigorous inspections at every stage, they are able to detect any defects or issues early on and address them promptly.

To further ensure quality, SourcifyChina Factory works closely with their suppliers to ensure that only top-quality materials are used in the manufacturing process. They have established strict guidelines and specifications that suppliers must adhere to in order to maintain consistent quality of the aluminum bending products. This partnership allows them to guarantee that all products meet the desired quality standards and specifications.

Since 2013, this client from the United States has purchased numerous filling machines for both CBD and eliquid oil.

What is the quality of aluminum bending work from SourcifyChina factory?

At SourcifyChina factory, the aluminum bending work is known for its high quality. Our skilled technicians use precision machinery and processes to ensure accurate and consistent results. We pay close attention to details and follow strict quality control measures to meet the highest standards. Our experienced team is dedicated to producing durable and reliable aluminum bendings that are suitable for a wide range of applications. Customers can trust SourcifyChina for consistently delivering top-notch quality aluminum bending work.

How does SourcifyChina ensure the quality of aluminum bending work?

Aluminum bending manufacturing requires precision and expertise to ensure high-quality results. When sourcing a factory in China, consider the following tips to ensure a successful partnership:

1. Experience: Look for a factory with extensive experience in aluminum bending manufacturing. Choose a supplier that has a proven track record of producing high-quality products.

2. Equipment: Ensure that the factory has the necessary equipment and tools to perform aluminum bending efficiently. This includes press brakes, rollers, and other machinery specific to aluminum bending.

3. Quality control: Verify that the factory has stringent quality control processes in place to guarantee the accuracy and consistency of the bending process. Insist on regular inspections and testing to uphold product quality standards.

Q: Can I source aluminum bending services from a factory in SourcifyChina?

A: Yes, you can definitely source aluminum bending services from a factory in SourcifyChina. SourcifyChina has a wide network of manufacturers and suppliers who specialize in various metal fabrication processes, including aluminum bending. By working with a factory in SourcifyChina, you can benefit from competitive pricing, high-quality products, and reliable lead times.

Additionally, SourcifyChina’s team of sourcing experts can help you find the right factory that meets your specific requirements for aluminum bending. They can assist with communicating your design specifications, negotiating pricing, and overseeing the production process to ensure that your products are manufactured to your exact specifications.

Sourcing aluminum bending services from a reputable factory in China can be a cost-effective solution for your manufacturing needs. Here are some tips to help you find the right supplier for your project:

1. Conduct thorough research: Start by researching different factories in China that specialize in aluminum bending services. Look for factories with a proven track record of quality and reliability.

2. Request quotes: Reach out to several factories and request quotes for your specific aluminum bending project. Be sure to provide detailed specifications and quantities to receive accurate pricing estimates.

3. Ask for samples: Before committing to a supplier, ask for samples of their work to ensure their quality meets your standards. This will also give you a better idea of their capabilities.

Copyright © 2024 SourcifyChina Fabrication | All Rights Reserved.