Top cable tray type in China introduce,list main products and website if have

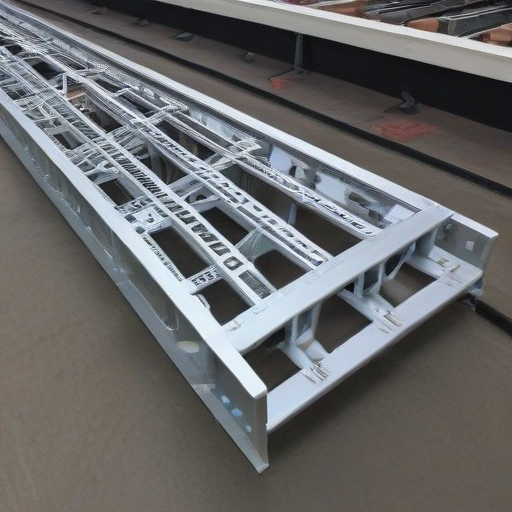

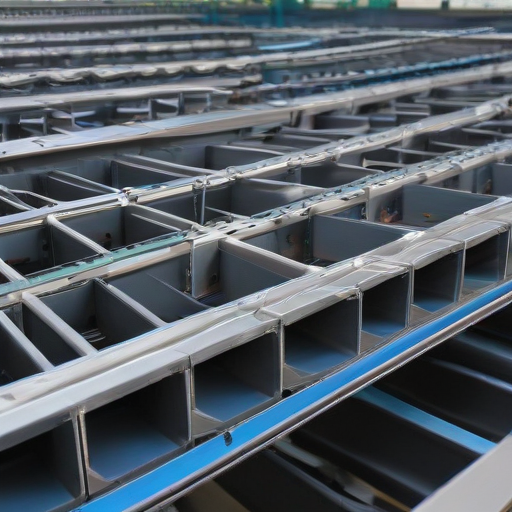

One of the top cable tray types in China is the ladder cable tray. This type of cable tray is made up of two side rails connected by rungs, resembling a ladder. It is commonly used for heavier cabling systems and provides strong support for cables.

Some main products of ladder cable trays in China include straight sections, fittings, and accessories such as bends, tees, and reducers. These products are available in various sizes and materials such as steel, aluminum, and FRP (fiberglass-reinforced plastic) to suit different installation requirements.

One of the leading manufacturers of ladder cable trays in China is Wuxi Yijie Machinery Equipment Co., Ltd. They offer a wide range of ladder cable tray products, including both standard and customized solutions to meet the specific needs of their customers. Their website is: http://www.wxyijie.com/

Wuxi Yijie Machinery Equipment Co., Ltd. is known for its high-quality products, competitive prices, and excellent customer service. They have a strong reputation in the industry and are trusted by many clients both in China and abroad.

Overall, ladder cable trays are a popular choice in China for organizing and supporting cables in various installations. With the wide range of products available from manufacturers like Wuxi Yijie Machinery Equipment Co., Ltd., customers can find the right cable tray solution for their specific project needs.

Types of cable tray type

There are several types of cable trays used in various industries for supporting and protecting cables. Some of the common types of cable trays are:

1. Ladder Tray: Ladder trays are one of the most popular types of cable trays and consist of two longitudinal side rails connected by rungs or cross members. These trays provide strong support for cables and are typically used in large industrial installations.

2. Perforated Tray: Perforated trays are similar to ladder trays but have perforations on the side rails to allow for better ventilation and drainage. These trays are used in areas where cables need to be protected from moisture or dust.

3. Wire Mesh Tray: Wire mesh trays are made up of welded wire mesh that provides a lightweight and flexible solution for cable support. These trays are easy to install and maintain and are commonly used in commercial and light industrial applications.

4. Solid Bottom Tray: Solid bottom trays have a solid base with raised sides to provide extra protection for cables. These trays are ideal for installations where cables need to be shielded from debris or moisture.

5. Trough Tray: Trough trays are U-shaped trays that provide a secure enclosure for cables. These trays are commonly used in heavy industrial applications where cables need extra protection from environmental factors.

Overall, choosing the right type of cable tray will depend on the specific requirements of the installation, such as the environment, cable load, and budget constraints. It is essential to consult with a cable tray specialist to determine the best type of tray for your project.

Pros and Cons of Using cable tray type

Cable tray type systems offer several advantages for organizing and protecting cables in industrial and commercial settings.

One of the main benefits of using cable trays is their versatility. They can be customized to fit the specific layout and requirements of a space, making them a flexible solution for managing cables. Additionally, cable trays are typically easier to install than conduit systems, which can save time and labor costs during the installation process.

Cable trays also provide good cable protection. They shield cables from damage caused by environmental factors such as moisture, dust, and heat. This can help prevent costly disruptions to operations and ensure the longevity of the cables.

However, there are some drawbacks to using cable trays as well. One potential disadvantage is the risk of electromagnetic interference (EMI) with sensitive electronic equipment. If not properly designed and installed, cable trays can act as large antennas that pick up and transmit electromagnetic signals, leading to interference issues.

Another downside is the potential for cable trays to accumulate dust and debris over time. This can create maintenance challenges and increase the risk of fire hazards if the buildup is not regularly cleaned.

In conclusion, cable trays offer a range of advantages for cable management, including flexibility, ease of installation, and cable protection. However, these systems can also present challenges such as EMI and maintenance issues that should be considered when choosing a cable management solution.

cable tray type Reference Specifications (varies for different product)

Cable trays come in various types based on the material they are made of, their design, and their intended use. Some common types of cable trays include ladder type, ventilated trough type, solid bottom type, and wire mesh type.

The ladder type cable tray is made of two side rails connected by regularly spaced rungs, resembling a ladder. This design provides easy access for maintenance and allows for good air circulation around the cables.

Ventilated trough type cable trays have solid metal or fiberboard covers with slots or holes for ventilation. This type of tray is ideal for applications where cables need protection from dust or water while still allowing for some airflow.

Solid bottom cable trays have a solid base with raised edges to contain the cables. This type provides additional protection for the cables and is often used in indoor applications where protection from external elements is necessary.

Wire mesh type cable trays are constructed of woven wire mesh or grid-like material. They are lightweight, cost-effective, and provide good visibility and air circulation for the cables.

When selecting a cable tray, it is essential to consider the specific requirements of the installation, such as the environment, load capacity, and cable management needs. Manufacturers provide detailed reference specifications for each type of cable tray to ensure proper installation and performance. By following these specifications and guidelines, users can ensure the safe and efficient management of their cables in any application.

Applications of cable tray type

Cable trays are versatile and widely used in various industries for managing and protecting electrical wiring and cables.

One application of cable trays is in commercial buildings such as offices, hospitals, and shopping centers. Cable trays are used to organize and route cables in a neat and orderly manner, which helps to prevent accidents caused by loose cables on the floor. In addition, cable trays provide easy access to cables for maintenance and repairs, reducing downtime and increasing efficiency.

Another common application of cable trays is in industrial settings such as manufacturing facilities, refineries, and power plants. In these environments, there are often large amounts of cables and wiring that need to be routed safely and securely. Cable trays provide a cost-effective solution for distributing power and communication cables, as well as protecting them from environmental hazards such as dust, moisture, and corrosion.

Cable trays are also used in data centers and telecommunications facilities to manage the large volume of cables required for networking and communication. Cable trays can support heavy loads of cables and provide proper ventilation to prevent overheating, ensuring optimal performance of the equipment.

Overall, cable trays are a versatile and reliable solution for managing cables in a wide range of applications, providing safety, organization, and efficiency in various industries.

Material of cable tray type

Cable trays are commonly made from various materials, each with its own set of advantages and disadvantages. The most common materials used for cable trays include:

1. Steel: Steel cable trays are known for their strength and durability, making them ideal for heavy-duty industrial applications. They are resistant to corrosion and can support large amounts of cables without bending or sagging. Steel cable trays are also easy to install and maintain.

2. Aluminum: Aluminum cable trays are lightweight and easy to handle, making them a popular choice for general-purpose applications. They are corrosion-resistant and can be easily customized to fit specific installation needs. However, aluminum trays may not be as strong as steel trays and may require additional support for heavy cable loads.

3. Stainless steel: Stainless steel cable trays offer excellent corrosion resistance, making them suitable for outdoor and harsh environment applications. They are also easy to clean and maintain, making them a hygienic option for food and beverage or pharmaceutical industries. Stainless steel trays are more expensive than other materials but offer long-term durability and reliability.

4. Fiberglass: Fiberglass cable trays are lightweight, non-conductive, and resistant to corrosion, making them ideal for use in environments where electrical conductivity is a concern. They are also easy to customize and install, as fiberglass can be molded into various shapes and sizes. However, fiberglass trays may not be as strong or durable as metal trays and may require additional support for heavy cable loads.

Ultimately, the choice of material for a cable tray will depend on the specific requirements of the installation, including the type of cables being used, the environment in which the tray will be installed, and the budget constraints. It is important to consider the factors of strength, durability, corrosion resistance, and conductivity when selecting the appropriate material for a cable tray.

Quality Testing Methods for cable tray type and how to control the quality

Quality testing methods for cable trays typically involve visual inspection, dimensional checks, material testing, and load testing.

Visual inspection involves examining the surface finish, welds, and overall appearance of the cable tray to ensure that there are no visible defects or damage. Dimensional checks ensure that the cable tray meets the specified dimensions and tolerances.

Material testing involves verifying the material composition of the cable tray, as well as conducting tests for corrosion resistance, impact resistance, and load capacity. Load testing is done to confirm that the cable tray can support the specified load without deforming or failing.

To control the quality of cable trays, it is important to establish clear quality standards and specifications for the manufacturing process. Regular inspection and testing should be conducted throughout the production process to identify any potential issues early on.

Additionally, implementing quality control measures such as process controls, quality audits, and employee training can help ensure that the cable trays meet the required quality standards. By monitoring and evaluating the quality of the cable trays at each stage of production, manufacturers can identify and address any quality issues before the products are shipped to customers.

Overall, implementing a comprehensive quality control program that includes testing methods, inspection procedures, and quality assurance measures can help ensure that cable trays meet the required quality standards and deliver reliable performance in various industrial applications.

The Work Process and how to use cable tray type

The work process of installing cable tray involves several steps to ensure proper functionality and safety. First, the cable tray type must be selected based on the specific needs and requirements of the project. Cable trays come in different materials such as steel, aluminum, or fiberglass, and varying designs like ladder, ventilated, or solid bottom.

Next, the cable tray route must be planned and mapped out to determine the best layout and installation method. This involves considering factors like cable weight, size, and quantity, as well as environmental conditions and regulations.

Once the route is determined, the cable tray should be properly supported and secured to ensure stability and durability. This may involve using brackets, hangers, or supports depending on the type of installation surface.

After the cable tray is securely in place, cables can be laid within the tray following proper guidelines for bundling, spacing, and securing. It is important to avoid overloading the cable tray and to leave enough space for future cable additions or modifications.

Finally, the cable tray should be inspected regularly to check for any damage, corrosion, or loose connections. Proper maintenance and periodic checks can help prevent accidents, downtime, and costly repairs.

In conclusion, the use of cable tray type in the work process involves careful planning, proper installation, and regular maintenance to ensure optimal performance and safety. By following these guidelines and not exceeding the recommended capacity of the cable tray, you can create a reliable and efficient cable management system for your project.

cable tray type Importing questions including Cost,Supplier,Sample,Certification and Market

1. What is the cost of importing cable tray type products?

The cost of importing cable tray type products can vary depending on the quantity, size, and quality of the products. It is important to negotiate with suppliers to get the best possible price for your order.

2. Can you recommend a reliable supplier for cable tray type products?

There are many suppliers of cable tray type products around the world. It is important to do thorough research and background checks on potential suppliers to ensure they are reliable and offer high-quality products at competitive prices.

3. Can I request a sample of cable tray type products before placing a bulk order?

Yes, most suppliers are willing to provide samples of their products before placing a bulk order. This allows you to inspect the quality of the products and make sure they meet your requirements.

4. Are cable tray type products required to have any certifications for import?

It is important to check the regulations and requirements in your country for importing cable tray type products. Some countries may require specific certifications or standards to ensure the products meet safety and quality standards.

5. What is the market demand for cable tray type products?

The market demand for cable tray type products can vary depending on the region and industry. It is recommended to conduct market research to understand the demand for these products in your target market before importing.

How to find and select check reliable cable tray type manufacturers in China

When looking for reliable cable tray manufacturers in China, there are a few key steps you can take to ensure you find a reputable supplier:

1. Research: Start by conducting thorough research online to identify potential manufacturers of cable trays in China. Look for companies with good reviews, a solid reputation, and experience in the industry.

2. Verify credentials: Check if the manufacturers are certified and comply with industry standards. Look for certifications such as ISO 9001, CE, UL, and CCC to ensure the quality of their products.

3. Request samples: Ask for samples of their cable trays to assess the quality of their products firsthand. This will also give you a better idea of their manufacturing capabilities.

4. Communicate: Reach out to the manufacturers and discuss your specific requirements and expectations. A reliable manufacturer will be responsive, transparent, and willing to provide you with all the information you need.

5. Visit the factory: If possible, arrange a site visit to the manufacturer’s factory to see their production process, quality control measures, and overall facilities. This will give you a better understanding of their operations and capabilities.

6. Get quotes: Compare quotes from multiple manufacturers to ensure you are getting a competitive price without compromising on quality.

By following these steps, you can find reliable cable tray manufacturers in China that meet your specifications and provide high-quality products. Remember to prioritize communication, quality, and credibility when selecting a manufacturer.

Background Research for cable tray type manufacturers Companies in China, use qcc.com archive.org importyeti.com

When looking for cable tray type manufacturers in China, some top companies to consider are Chogori Technology Co., Ltd, Ningbo Sunter International Trade Co., Ltd, and Shanghai Xuanzhi Industry Co., Ltd.

Chogori Technology Co., Ltd is a leading manufacturer of cable trays in China. They offer a wide range of cable tray types including ladder cable trays, perforated cable trays, and wire mesh cable trays. Chogori Technology Co., Ltd is known for their high-quality products and competitive pricing.

Ningbo Sunter International Trade Co., Ltd is another reputable manufacturer of cable trays in China. They specialize in producing cable trays that are durable and easy to install. Ningbo Sunter International Trade Co., Ltd has a strong reputation for providing excellent customer service and on-time delivery.

Shanghai Xuanzhi Industry Co., Ltd is a well-established manufacturer of cable trays in China. They offer a variety of cable tray types including PVC cable trays, steel cable trays, and aluminum cable trays. Shanghai Xuanzhi Industry Co., Ltd is known for their innovative designs and customized solutions for cable management.

Overall, these companies are highly regarded in the industry and have a track record of providing top-quality products to customers in China and around the world. It is recommended to reach out to these companies directly for more information on their products and services.

Price Cost Research for cable tray type manufacturers Companies in China, use temu.com and 1688.com

Using temu.com and 1688.com to research the price costs for cable tray type manufacturers in China, it was found that the prices vary depending on the size, material, and quality of the products. On temu.com, prices for cable trays range from $2.50 to $10 per meter, with a minimum order quantity of 100 meters. The prices on temu.com are generally higher compared to that on 1688.com.

On 1688.com, prices for cable trays start from as low as $1.50 to $5 per meter, with a minimum order quantity of 50 meters. The prices on 1688.com are more competitive and affordable compared to that on temu.com. It is important to note that the prices may vary based on the specifications and customization of the cable trays.

Overall, both temu.com and 1688.com offer a wide range of options for cable tray type manufacturers in China. It is recommended to compare prices and quality from different suppliers to find the best deal for your specific needs. It is also important to consider factors such as shipping costs, lead time, and customer reviews when making a purchasing decision.

Shipping Cost for cable tray type import from China

The shipping cost for importing cable trays from China can vary depending on several factors such as the size and weight of the trays, the shipping method chosen, and the destination country. Generally, the cost of shipping cable trays from China to most countries is calculated based on the weight or volume of the cargo.

For example, if you are importing a small quantity of cable trays, the cost of shipping can range from $200 to $500 for air freight, while sea freight may cost between $150 to $300 per cubic meter. If you are importing larger quantities, the shipping cost per unit may decrease.

It is important to note that additional charges such as customs duties, taxes, and import fees may also apply when importing cable trays from China. These charges can vary depending on the destination country’s regulations and policies.

To minimize shipping costs, it is recommended to compare quotes from different shipping providers and choose the most cost-effective option. Consolidating shipments, optimizing packaging to reduce volume, and planning ahead can also help reduce shipping expenses.

Overall, it is essential to consider all factors when calculating shipping costs for importing cable trays from China to ensure a smooth and cost-effective logistics process.

Compare China and Other cable tray type Markets: Products Quality and Price,Visible and Hidden Costs

China is a dominant player in the cable tray market, offering a wide range of products at competitive prices. The quality of cable trays produced in China is generally good, as manufacturers adhere to strict standards and regulations. However, there may be variations in quality depending on the manufacturer.

In other markets, such as those in Europe or North America, cable tray products are known for their high quality and durability. The prices of cable trays in these markets are typically higher than those in China due to the higher cost of production and labor. However, consumers in these markets are willing to pay a premium for the assurance of superior quality.

In terms of visible and hidden costs, purchasing cable trays from China can result in lower upfront costs compared to buying from other markets. However, there may be hidden costs associated with shipping, customs duties, and potential delays in delivery when importing from China. On the other hand, products from more established markets may have higher upfront costs but come with fewer hidden costs and risks.

Overall, the decision to purchase cable tray products from China or other markets will depend on factors such as budget, quality requirements, and time constraints. While China offers competitive prices and a wide range of products, other markets may provide higher quality and more reliable products with fewer hidden costs. It is important for buyers to carefully weigh these factors before making a decision.

Custom Private Labeling and Branding Opportunities with Chinese cable tray type Manufacturers

Are you looking for custom private labeling and branding opportunities with Chinese cable tray manufacturers? Look no further! Our partners in China offer a wide range of high-quality cable tray products that can be customized with your own branding and logo.

By working closely with our manufacturers, we can help you create a unique and personalized product that meets your specific requirements and specifications. Whether you need a custom color, size, or design, our team can work with you to bring your vision to life.

With our extensive network of Chinese manufacturers, we can offer competitive pricing and fast turnaround times on all of our custom private labeling and branding projects. We understand the importance of standing out in a crowded market, and our customized cable trays are the perfect way to showcase your brand and attract new customers.

Don’t miss out on this exciting opportunity to elevate your brand and increase your visibility in the market. Contact us today to discuss your private labeling and branding needs with our team of experts. Let us help you take your business to the next level with our custom cable tray solutions from China.

Tips for Procurement and Considerations when Purchasing cable tray type

When purchasing cable trays, there are several important factors to consider to ensure you select the right type for your needs:

1. Determine the type of cable tray needed: There are various types of cable trays available, including ladder, solid-bottom, wire mesh, and basket trays. Consider the specific requirements of your project to determine which type will best meet your needs.

2. Consider the material: Cable trays are available in different materials, such as steel, aluminum, and fiberglass. Each material has its own advantages and disadvantages, so consider factors such as durability, corrosion resistance, and cost when selecting the material for your cable tray.

3. Size and load capacity: Consider the size and load capacity requirements of your cable tray to ensure it can accommodate the cables and support the weight of the cables without sagging or bending.

4. Installation requirements: Consider the installation requirements of the cable tray, including the location, mounting options, and any additional accessories needed for installation.

5. Cost: Compare prices from different suppliers to ensure you are getting the best value for your money. Consider not only the initial cost of the cable tray but also the long-term maintenance and operational costs.

By taking these factors into consideration, you can ensure that you select the right type of cable tray for your needs and budget.

FAQs on Sourcing and Manufacturing cable tray type in China

1. How can I source cable tray types in China?

You can source cable tray types in China by connecting with manufacturers, suppliers or distributors either through online platforms, trade shows, or by using sourcing agents. It is important to conduct thorough research, verify the credentials of the suppliers, and ensure quality standards are met before making a purchase.

2. What factors should I consider when selecting a manufacturer in China for cable tray types?

When selecting a manufacturer in China for cable tray types, it is important to consider factors such as the company’s reputation, experience in the industry, production capabilities, quality control measures, compliance with regulations, pricing, and lead times. Visiting the manufacturer’s facilities and conducting factory audits can also help in making an informed decision.

3. Can I customize cable tray types in China?

Yes, many manufacturers in China offer customizations for cable tray types to meet the specific requirements of their clients. You can work closely with the manufacturer to discuss your design specifications, materials, finishes, and any other customizations needed for your project.

4. How can I ensure quality control when manufacturing cable tray types in China?

To ensure quality control when manufacturing cable tray types in China, you can implement measures such as conducting regular inspections during production, testing samples for quality standards, specifying quality requirements in the contract, and working closely with the manufacturer to address any issues that may arise. Engaging with manufacturers who have certifications such as ISO or UL can also help in ensuring quality control.

5. What are the common lead times for manufacturing cable tray types in China?

The lead times for manufacturing cable tray types in China can vary depending on factors such as the complexity of the design, customization requirements, production capacity of the manufacturer, and order quantity. Typically, lead times can range from a few weeks to several months, so it is important to discuss and agree on lead times with the manufacturer before placing an order.

Why contact sourcifychina.com get free quota from reliable cable tray type suppliers?

Sourcifychina.com is a reputable sourcing platform that specializes in connecting businesses with reliable suppliers in China. By contacting Sourcifychina.com, you can access a network of verified cable tray type suppliers who offer high-quality products at competitive prices.

By requesting a free quota from Sourcifychina.com, you can quickly and easily compare quotes from multiple suppliers to find the best deal for your business. This allows you to save time and money by cutting out the hassle of contacting suppliers individually.

Sourcifychina.com carefully vets all suppliers to ensure they meet their strict quality standards, so you can trust that you are getting the best possible products for your needs. Additionally, Sourcifychina.com provides ongoing support and assistance throughout the sourcing process to ensure a smooth and successful transaction.

Overall, by utilizing Sourcifychina.com’s platform to connect with reliable cable tray type suppliers, you can streamline your sourcing process, access competitive pricing, and secure high-quality products for your business. Requesting a free quota is a simple and effective way to get started and find the perfect supplier for your needs.