-

- Industry

- Material

- Capability

- Products

- Blog

- Sitemap

- Newsletter

- Whatsapp 8615951276160

- Industry

- Material

- Capability

- Products

- Blog

- Sitemap

Enhancing your Supply Chain with Reliable Metal Finishes from SourcifyChina’s Trusted Factories

SourcifyChina is the leading platform for sourcing high-quality metal finishes from reputable factories in China. With our extensive network of suppliers, we offer a wide range of finishing options to meet your specific requirements.

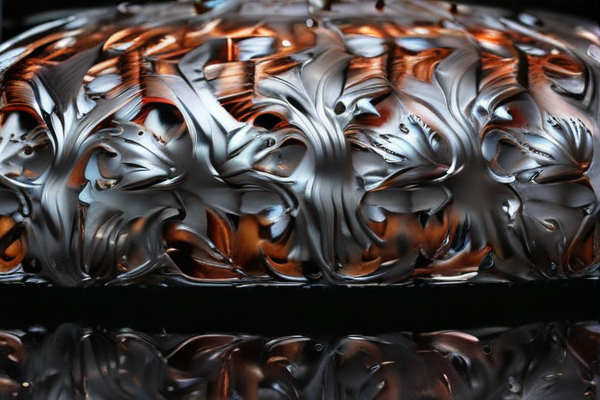

Our factories are equipped with state-of-the-art technology and experienced craftsmen who are dedicated to delivering top-notch results. Whether you need plating, powder coating, anodizing, or any other type of metal finish, we have you covered.

We understand the importance of quality assurance and strict production standards when it comes to metal finishes. That’s why we work closely with our factories to ensure that every piece that comes off the production line meets our high standards for durability, aesthetics, and consistency.

SourcifyChina Factory is the top choice for buyers seeking finished metal products from China. With years of experience in sourcing, they offer high-quality finishes at competitive prices.

Their network of trusted suppliers ensures consistent quality and timely delivery of finished metal products. SourcifyChina Factory also provides personalized service to meet the specific needs of each buyer.

By choosing SourcifyChina Factory, buyers can benefit from cost-effective solutions and access to a wide range of finishing options. Their expertise in the metal industry guarantees customer satisfaction and peace of mind.

In conclusion, SourcifyChina Factory is the ideal choice for buyers looking to purchase finishes for metals from China. With their reputation for excellence and commitment to customer service, buyers can trust that their finished products will meet the highest standards of quality and precision.

Using this technique, we turn flat metal sheets into different parts by bending, perforating, cutting, and designing. Every sheet metal can be transformed into many different forms. However, we carefully select the materials. We used high-end aluminum sheets, steel sheets, stainless steel, brass, and more. According to your exact specifications, we guarantee high-precision car sheet metal parts.

In a professional way, KDM can work with you anytime you need sheet metal components and our services. We are a well-established company with wide experience working with automotive businesses worldwide. Here, we assure you can get premium parts at fair prices. Contact us today!

Some common finishes for metals include polished, brushed, anodized, plated, powder-coated, antiqued, patinated, waxed, lacquered, and painted. These finishes enhance aesthetics, durability, and corrosion resistance.

1. Plating: Applying a thin layer of a different metal to protect and enhance the appearance of the base metal.

2. Coating: Painting, powder coating, or another method of covering the metal to provide a protective or decorative finish.

3. Anodizing: Creating a protective oxide layer on the metal surface by electrolysis, providing increased corrosion resistance and color options.

4. Polishing: Buffing the surface of the metal to a smooth, shiny finish, enhancing its appearance and removing imperfections.

5. Patination: Intentionally inducing oxidation on the surface of the metal to create a unique, aged look or finish.

6. Lacquering: Applying a clear coating to the metal to protect it from corrosion and scratches while maintaining its original appearance.

1. Electropolishing: smooths surfaces, removes impurities, enhances corrosion resistance.

2. Coating: protective layers like paint, powder coating, anodizing.

3. Passivation: removes free iron, improves corrosion resistance.

4. Plating: electrolytically deposits metals like chrome, nickel, zinc.

5. Polishing: buffs surfaces to a high shine, improves appearance.

6. Oxidizing: creates a protective oxide layer, enhances durability.

1. Anodizing: creates a protective oxide layer on the surface.

2. Galvanizing: applies a zinc coating to prevent corrosion.

3. Powder coating: electrostatically applies a dry powder for a durable finish.

Finishes for metals include polishing, powder coating, anodizing, plating, and patina, all providing different appearances and protection against corrosion or wear.

1. Plating: applying a thin layer of metal to enhance appearance and corrosion resistance.

2. Coating: protecting metal surfaces with a durable finish like paint or powder coating for added durability.

3. Polishing: creating a smooth, shiny surface by rubbing with a polishing compound or abrasive material.

4. Anodizing: enhancing the durability and appearance of metal by creating a protective oxide layer through electrolysis.

5. Oxidizing: intentionally corroding metal to create a unique patina or rust finish for decorative purposes.

Each component has an excellent heat resistance and further outstanding properties. They don’t corrode, stain, or break easily.

We provide accurate fabrication services for your car sheet metal. They have high-precision designs and properties.

We offer our services for your car sheet metal at a low price. We ensure better quality yet reasonable models.

All our car sheet metal components have less maintenance. They are also easy to install and easily repairable.

There are various types of finishes available for metals, including powder coating, anodizing, plating, and painting. Each option offers different benefits in terms of durability, appearance, and protection against corrosion.

– Powder coating: provides a durable, long-lasting finish that is resistant to chipping and scratching.

– Anodizing: creates a hard, corrosion-resistant surface by forming a protective oxide layer.

– Plating: involves covering the metal with a thin layer of another metal, such as gold or chrome, for added aesthetics and protection.

– Painting: offers a wide range of color options and can provide a protective barrier against moisture and chemicals.

We used these materials for creating bulkheads, dashboards, and other car parts because of their malleability, softness, and lightweight properties. They also produce attractive polish and do not corrode, unlike other materials. We made them unbreakable as well. However, car parts made of aluminum are the most recommended ones, especially if you need durable parts for car repair or custom interior restoration.

There are a variety of applications for finishes for metals in various industries such as construction, automotive, and electronics. Finishes can provide protection against corrosion, enhance appearance, and improve durability.

– Protection against corrosion

– Enhancement of appearance

– Improvement of durability

– Resistance to abrasion and wear

– Increased thermal and electrical conductivity

– Prevention of tarnishing and oxidation

– Creation of unique textures and finishes

– Promotion of adhesion for coatings or paints

– Reduction of friction and wear

– Easy maintenance and cleaning requirements.

The process is used in modifying and customizing automobile components. It is also required for precise roll-bar fabrication, vintage reconditioning, fixing or restoration process, and body reforming. So, if you are part of the automotive industry and you need a custom car parts supplier and fabrication professional, choose KDM!

The SourcifyChina Factory finishes for metals market is a thriving industry that offers a wide range of finishes to enhance the appearance and durability of metal products. From traditional finishes like polishing and anodizing to more advanced techniques such as powder coating and electroplating, manufacturers in China are able to meet the diverse needs of their clients. With a focus on quality and precision, Chinese factories have gained a reputation for producing high-quality finishes at competitive prices, making them a popular choice for businesses seeking to outsource their metal finishing needs.

The “Sourcify China Factory finishes for metals” application is a valuable tool for equipment manufacturing companies looking to source high-quality metal finishes for their products. With this application, manufacturers can easily connect with reputable metal finishing factories in China that specialize in providing a wide range of finishes, including powder coating, anodizing, and plating. By utilizing this service, equipment manufacturers can ensure that their products are not only visually appealing but also durable and resistant to corrosion.

Sourcify’s China Factory finishes for metals offer a wide range of benefits to industries looking to enhance the quality and durability of their products. These finishes provide a protective layer that helps prevent corrosion, wear and tear, and other damage that can compromise the integrity of metal components. Industries such as automotive, aerospace, and construction can benefit from these finishes to ensure that their products meet high-quality standards and have a longer lifespan.

Additionally, Sourcify’s China Factory finishes for metals can also improve the aesthetics of metal products, making them more attractive and appealing to consumers. These finishes can be customized to achieve a variety of textures, colors, and finishes, allowing industries to create unique and eye-catching products that stand out in the market. By investing in these finishes, industries can differentiate their products from competitors and attract more customers, ultimately leading to increased sales and revenue.

KDM performs fabrication processes depending on your applications. If automotive parts are used as seats, door panels, or body panels, we can provide custom fabrication. Step by step processing starts from:

SourcifyChina finishes for metals undergo a rigorous quality control manufacturing process to ensure the highest standard of products. The first step involves inspecting raw materials for any defects or inconsistencies.

Once the materials pass inspection, they are sent to the production line where skilled workers use advanced technology and equipment to craft the metal finishes. Throughout the production process, quality checks are conducted to ensure each finished product meets specifications.

After the finishes are completed, a final round of quality control inspections is performed to verify the durability, finish, and overall appearance of the products. Any items that do not meet the quality standards are rejected and must be reworked or discarded.

SourcifyChina offers extensive capabilities in sourcing metals, including aluminum, steel, copper, and more. With a vast network of suppliers, they can provide high-quality materials at competitive prices.

Their team of experts conducts thorough supplier vetting processes to ensure reliability and quality. They also offer personalized sourcing solutions to meet specific requirements and budget constraints.

SourcifyChina leverages their in-depth knowledge of the industry to negotiate favorable terms with suppliers, allowing them to provide cost-effective options for their clients. They also prioritize timely delivery and excellent customer service throughout the sourcing process.

In conclusion, SourcifyChina’s comprehensive capabilities in metal sourcing, combined with their commitment to quality and customer satisfaction, make them a trusted partner for businesses looking to procure metals efficiently and affordably.

By providing car sheet metal fabrication, we can create different car parts with excellent precision. All final auto components are engineered according to your requirements. Each part is perfect for car restoration, repair, and replacement.

We are fully capable of producing unique yet cheaper customized pieces. We are supported with advanced machines, including pipe benders, stretchers, cutting tools, and more. With more than decades of experience, KDM delivers precision and aesthetics to your projects.

Finishes for metals provide both aesthetic appeal and enhanced protection for the material. By applying different finishes to metals, you can achieve a variety of looks and improve the longevity of the metal surface.

– Protection against corrosion and rust

– Increased durability and longevity

– Easy to clean and maintain

– Improved resistance to scratches and abrasions

– Enhanced appearance and aesthetic appeal

– Can be used to customize the look of metal surfaces

– Provides a smooth and polished finish

– Can add texture or sheen to metal surfaces

– Different finishes can achieve different effects (e.g. matte, glossy, etc.)

Toughness: We offer automotive parts with extreme toughness. It is made from high-grade and durable sheet metals.

There are various finishes available for metals that not only enhance their appearance but also provide protection against corrosion.

– Anodizing: Creates a durable, corrosion-resistant oxide layer on the metal surface.

– Plating: Adds a thin layer of another metal to improve appearance and increase resistance to wear.

– Polishing: Achieves a smooth, reflective surface by removing imperfections and scratches.

– Powder coating: Provides a durable, attractive finish by applying a powder that is baked onto the metal.

– Painting: Offers endless color options and can be used to customize the appearance of the metal.

– Galvanizing: Coats the metal with a layer of zinc to prevent corrosion and extend its lifespan.

– Patination: Creates an aged or weathered appearance through chemical treatments.

Toughness: We offer automotive parts with extreme toughness. It is made from high-grade and durable sheet metals.

SourcifyChina finishes for metals are top-notch, providing the perfect touch to custom products. The finishes add an extra layer of quality and sophistication to any project.

Whether it’s a simple design or a complex masterpiece, SourcifyChina has the expertise to provide the perfect finish for metal products. Their attention to detail and dedication to quality are unmatched.

From chrome plating to powder coating, SourcifyChina offers a wide range of finishes for metals. Their team of experts ensures that each product receives the right treatment for a flawless result.

No matter the size or scope of the project, SourcifyChina finishes for metals can elevate the look and feel of any custom product. Their commitment to excellence shines through in every finish, making them the go-to choice for all custom metal projects.

1. Metal finishes add character and protection to surfaces.

2. Different finishes like polished, brushed, or matte create unique looks for metals.

3. Finishes can enhance the durability and appearance of metals, making them versatile in various industries.

1. Galvanizing – a coating of zinc is applied to prevent corrosion and increase durability.

2. Anodizing – an electrochemical process that creates a protective oxide layer on the metal surface.

3. Powder coating – a dry finishing process where powdered paint is electrostatically applied and baked on for a durable finish.

4. Plating – a thin layer of a different metal is deposited onto the surface for improved appearance and protection.

5. Polishing – the metal is buffed to a glossy finish using abrasives for a smooth and shiny appearance.

Finishes for metals include polishing, plating, powder coating, anodizing, and painting. These finishes improve appearance, durability, and corrosion resistance for a variety of applications.

1. Electroplating with a protective layer of another metal to improve durability and resistance to corrosion.

2. Buffing and polishing to achieve a smooth and shiny surface.

3. applying a clear coat or lacquer to protect the metal from oxidation and scratches.

Some common finishes for metals include polished, brushed, satin, antique, hammered, and matte. These finishes can enhance the appearance and durability of metal surfaces.

SourcifyChina is a leading sourcing company that specializes in finding high-quality finishes for metals. With a vast network of suppliers and manufacturers, they are able to deliver top-notch finishes that meet the specific requirements of their clients. Whether it’s plating, powder coating, anodizing, or any other type of finish, SourcifyChina has the expertise and resources to source the best options at competitive prices. Their attention to detail and commitment to customer satisfaction make them a trusted partner for businesses looking to enhance the quality and appearance of their metal products. By working with SourcifyChina, companies can be confident that they will receive top-of-the-line finishes that elevate the overall quality of their products and drive customer satisfaction.

In the aerospace industry, the application of finishes for metals is critical for enhancing the performance and longevity of aircraft components. One widely used finish is anodizing, where a protective oxide layer is created on the metal surface through an electrochemical process. Anodizing helps to improve corrosion resistance, increase wear resistance, and provide better adhesion for paints and adhesives. This makes it an ideal finish for aerospace components exposed to harsh environments, such as aircraft bodies, wings, and landing gear.

Another commonly used finish in the aerospace industry is chromate conversion coating, also known as alodine or yellow chromate. This finish provides excellent corrosion resistance, improves paint adhesion, and serves as a base for other coating options. Chromate conversion coatings are often applied to aluminum components in aircraft structures, such as fuselages, wing panels, and fasteners.

The hardware industry relies heavily on the application of finishes for metals to provide both aesthetic appeal and functional benefits. One common finish used in this industry is powder coating, which offers excellent durability and resistance to corrosion, making it ideal for products exposed to harsh environments. Powder coating also allows for a wide range of color options, enabling manufacturers to customize the look of their products to meet customer preferences. Additionally, powder coating is a more environmentally friendly option compared to traditional liquid paint finishes, as it produces less waste and contains fewer harmful chemicals.

The electronic industry utilizes various finishes for metals to enhance the durability, conductivity, and appearance of electronic components. One common finish applied to metals in the electronic industry is electroplating, where a thin layer of metal is deposited onto the surface of the component through an electrochemical process. This finish is used to provide corrosion resistance, improve solderability, and create a more aesthetically pleasing appearance. In addition to electroplating, metals in the electronic industry are also often coated with other finishes such as anodizing, which creates a protective oxide layer on aluminum components to prevent corrosion and improve insulation properties.

Finishing plays a crucial role in the automotive industry for metals as it not only enhances the aesthetic appeal but also provides protection against corrosion and wear. Various types of finishes are applied to metal surfaces in automobiles, such as painting, powder coating, plating, and anodizing. These finishes help to improve the durability of the vehicle and enhance its overall appearance. For example, a high-quality paint finish not only adds color to the car but also protects the body from environmental factors such as sunlight, moisture, and pollutants. Similarly, plating finishes like chrome or nickel provide a shiny appearance to metal parts while also preventing rust and corrosion.

The medical industry relies heavily on the use of metals in various applications such as surgical instruments, medical implants, and hospital equipment. In order to ensure the safety and effectiveness of these metal components, it is crucial to apply finishes that can enhance their corrosion resistance, improve biocompatibility, and increase their durability. For example, stainless steel surgical instruments are often coated with a thin layer of titanium nitride or diamond-like carbon to reduce friction, improve wear resistance, and protect against the harsh chemical environments found in medical settings. This not only extends the lifespan of the instruments but also ensures that they remain sharp and sterile for repeated use.

What is the quality of finishes for metals work from SourcifyChina factory?

Our finishes for metals work from SourcifyChina factory are of high quality and meet industry standards. We ensure that the finishes are durable, aesthetically pleasing, and meet the specifications provided by our clients. Our factory uses advanced technology and processes to ensure that the finishes are of the highest quality.

What types of finishes for metals are available from SourcifyChina factory?

We offer a wide range of finishes for metals, including but not limited to polishing, plating, painting, anodizing, and powder coating. Our factory has the capability to provide custom finishes based on the specific requirements of our clients.

How does SourcifyChina factory ensure the quality of finishes for metals work?

When it comes to finishes for metals manufacturing from a SourcifyChina factory, there are several options to choose from to achieve the desired look and durability for your products. Some common finishes for metal manufacturing include powder coating, anodizing, plating, polishing, and painting.

Powder coating is a popular finish for metal products as it provides a durable and attractive finish that is resistant to corrosion, abrasion, and chemicals. This finish is applied as a dry powder and then cured under heat to create a uniform and long-lasting finish.

Anodizing is another popular finish for metals like aluminum, which enhances the natural properties of the metal while providing increased corrosion resistance and durability. This finish can come in a variety of colors and can be further enhanced with additional processes like dyeing or sealing.

What finishes for metals can I source from SourcifyChina factory?

You can source a variety of finishes for metals from SourcifyChina factory, including but not limited to powder coating, anodizing, electroplating, galvanizing, and polishing. These finishes can be customized to meet your specific requirements in terms of color, texture, thickness, and durability. SourcifyChina’s team of experienced manufacturers and suppliers is well-equipped to provide high-quality metal finishes that will enhance the appearance and longevity of your metal products. Additionally, they can offer guidance on selecting the most suitable finish for your specific application and budget.

When sourcing finishes for metals from a factory in China through Sourcify, there are a few tips to keep in mind to ensure the best results.

1. Research Different Finishes: Before reaching out to factories, research the different finishes available for metals. Some common finishes include powder coating, electroplating, anodizing, and polishing. Understanding your options will help you make informed decisions.

2. Clearly Define Your Requirements: When communicating with factories, clearly define your requirements for the finishes. Provide details such as the type of metal, desired finish, color, thickness, and any specific requirements for the application.

3. Request Samples: To ensure the quality of the finishes, request samples from the factory before placing a bulk order. This will allow you to test the finishes and make any necessary adjustments before production.

Copyright © 2024 SourcifyChina Fabrication | All Rights Reserved.